Tungsten Oxide Thin Film Chemical Vapor Deposition Method

Chemical vapor deposition method is to introduce reactants into substrate surface, which is a common method for producing thin film. The present thin film forming method mainly includes metal organic chemical vapor deposition method(MOCVD ) and low pressure chemical vapor deposition method(LPCVD).

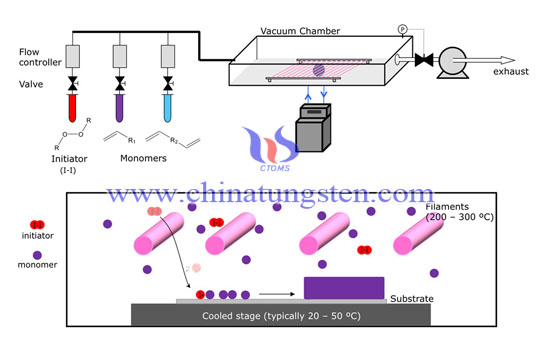

Metal organic chemical vapor deposition method is a method of heteroepitaxial growth, it is an effective method of forming high quality thin film. Below is the sketch map of MOVCD. Normally it applies organo metal as the metal source, Ar is applied as carrier gas, reaction gases are mainly O2 or stream. Thin film produced by MOVCD has high crystalline quality and smooth surface, the film is uniform.

Low pressure chemical vapor deposition is prepared under moderate vacuum atmosphere (about 0.1 -5torr), low producing temperature, it can be deposited on substrate of large area, the deposition process is easy to control, also the surface of deposited thin film is flatness.

The common chemical vapor deposition method usually uses gas compound includes hydrogen and chloride, when producing tungsten oxide thin film, the W(CO)6 and other tungsten compound are used as precursor, along with W atom and there are chemical reaction on the surface of substrate. There are also reports of using other specialized metal organic vapor molecules to prepare tungsten oxide films by metal organic chemical vapor deposition (OMCVD), Plasma enhanced chemical vapor deposition (PECVD)is carried out under the influence of the plasma glow discharge, it can increase the rate of thin film deposition.

Deposition rate of tungsten oxide film prepared by CVD is faster than any other producing method, the method has the advantages of versatility, product is of high purity, good process controllability, excellent process continuity, but the cost is too high which is not suitable for industrial production.